we are industry

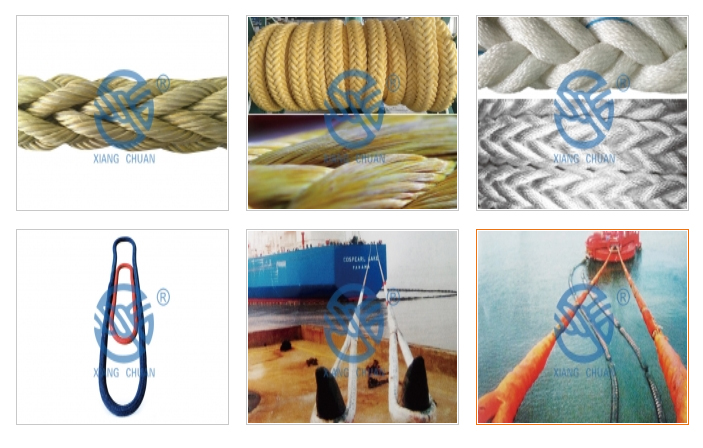

8 strand marine Mooring Rope are one of the particularly important tension elements carried by ships. Their main function is to connect the ship to the ground and stabilize the ship at sea or in the port. The selection of cable materials and the size of the rope diameter play a crucial role in its tensile strength, wind and wave resistance, corrosion resistance and service life.

As for the relationship between the strength and length of 12 strand Marine Mooring Rope, the composition, nature and type of the cables should be analyzed. Cables are generally made of multiple steel wires or fiber filaments twisted together. According to different compositions and manufacturing processes, they can be divided into three types, eight strands, and double Braided Ropes. Currently, the commonly used cable materials mainly include steel wire, artificial fiber and natural fiber.

Steel wire rope is a common type of Marine Rope. It has the advantages of high strength, corrosion resistance, and long service life. It is widely used in various ship and dock unloading situations. The strength and length of steel wire ropes are mainly related to their diameter and structure. Generally speaking, the larger the diameter and the tighter the structure, the higher the strength. The length is selected based on different needs and expansion characteristics.

Man-made fiber Double Braided Marine Mooring Rope refer to cables spun from various man-made fibers (including polyester, polyamide, polypropylene, polyethylene, etc.). They are light-weight, soft, corrosion-resistant, and have good elongation and condensation properties. Features. In ship operations and marine development, man-made fiber ropes are safer and more reliable than steel wire ropes. Since the strength of man-made fiber ropes is mostly related to their length, the longer the length, the lower the strength. Therefore, appropriate lengths and specifications should be selected according to different ships and operating situations.

Natural fiber cables refer to cables spun from plant fibers (such as flax, hemp, jute, palm, etc.). They have the characteristics of light weight, softness, good elasticity, good water absorption and heat insulation. However, because natural fiber cables are easy to absorb water and wear easily, they need to be maintained and replaced in time during use. There is also a certain correlation between the strength and length of natural fiber cables. Generally speaking, the longer the length, the lower the strength.

Therefore, the relationship between the strength and length of marine cables requires a detailed analysis of factors such as their material, structure, and use environment. When selecting cables, comprehensive considerations should be made based on actual needs and appropriate lengths and specifications should be selected to ensure the safe transportation of ships and cargo. At the same time, attention needs to be paid to the maintenance and replacement of cables during use, and problems such as cable wear and damage need to be checked promptly to ensure the service life and safety of the cables.

Address:

No.8 Chengnan road,chengnan industry park,Baoying county,Jiangsu China

Email:

E-mail1:vanzer@xcrope.com Vanzer Tao

E-mail2:sales@xcrope.com Wang Peng

E-mail3:grace@xcrope.com Grace Li

E-mail4:info@xcrope.com David Cheng

Company phone:

+86-514-88253368

Overseas sales department:

+86-514-88302931

Copyright By © Jiangsu Xiangchuan Rope Technology Co., Ltd. | All Rights Reserved